Optimize processes and make them more efficient with AI

Artificial intelligence (AI) methods are making their way onto factory floors. AI is a tool, and as with any other tool, a decision has to be made as to whether and when its use makes sense or not – says Prof. Marco Huber of the Fraunhofer Institute for Manufacturing Engineering and Automation IPA. In an exclusive interview with Schall-Messen, he explains to us that there are many good reasons why humans and AI systems can and should work hand in hand. And shows a practical way for SMEs to get started with AI.

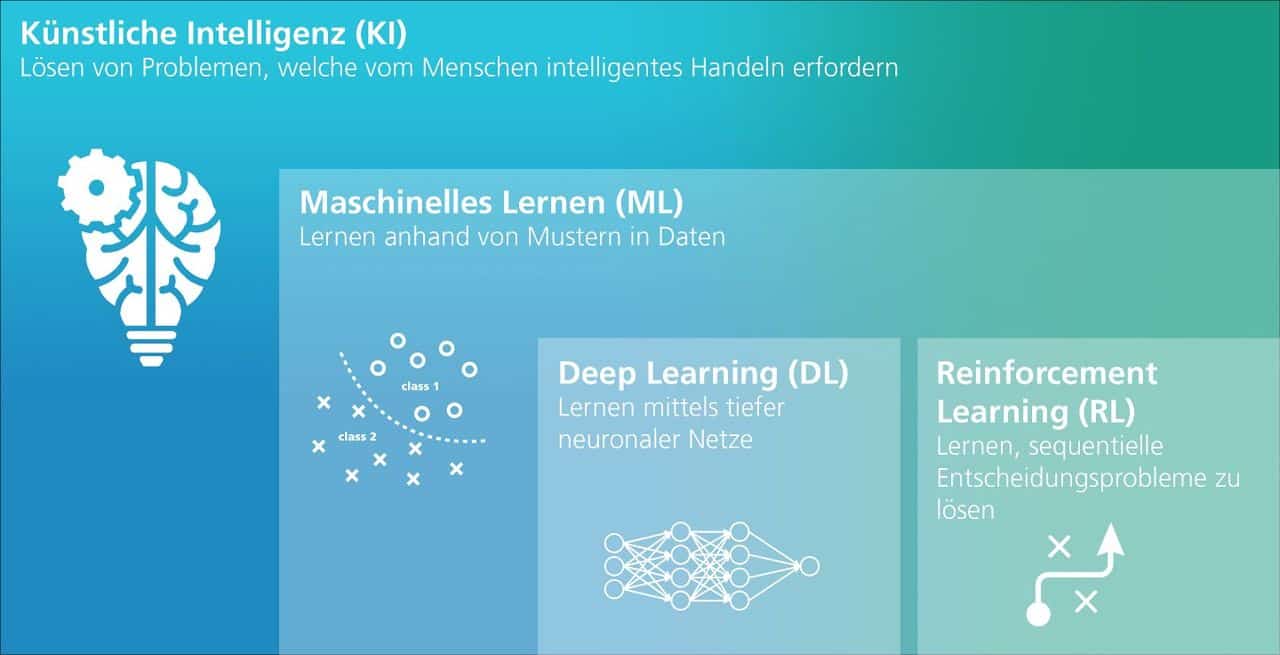

Professor Huber, it is said that artificial intelligence (AI) is making its way into industrial manufacturing – there is also talk of machine learning or deep learning. For clarification, please give us your definitions and delineations.

Unfortunately, there is no clear definition of the term AI. For me, Artificial Intelligence is about solving problems that require humans to act intelligently. In addition to machine learning, currently the most active subfield, planning and search algorithms, logic or robotics are also part of AI. The AI subfield of machine learning uses patterns in data to make data-based decisions. The term “learning” refers to recognizing these patterns and transferring them into a statistical model that can then be applied to new data. There are many different types of models. Currently very popular are the artificial neural networks, which have been modeled approximately on the human nerve cells (neurons) in the brain. If these networks consist of a large number of layers, i.e. if they are deep, they are referred to as “deep learning”.

AI has been a research topic for several decades, but it has only really taken off in recent years due to the strong computing power, big data and intelligent algorithms available. AI offers a great many opportunities, but the path from research results to practice is often still difficult for companies due to a lack of knowledge or resources. Another challenge is the “black box” nature of many ML-based methods. This means that even experts cannot always understand exactly why a result was reached. This can lead to legal problems, but also to a lack of trust and acceptance on the part of users. Therefore, we are intensively researching methods for the explainability of AI processes (xAI, explainable AI).

In which areas of production are processes with AI already in use? Where does AI make sense on the factory floor – and where not at all?

One of the classic applications in the field of artificial intelligence is quality inspection using camera systems. In this context, camera-based systems supplement humans as quality inspectors or take over this task completely if an automated solution offers sufficient added value. For example, when it comes to detecting damage in the vehicle paint or inspecting weld seams. The image data is increasingly analyzed using algorithms that can be attributed to the field of artificial intelligence.

Another field of application is predictive maintenance. The idea is to know in advance when the service life of a particular production machine will end, thus maximizing the machine’s use before it breaks down. At the time of the failure, the repair crew and the required spare parts can then already be ready. Special algorithms from the AI environment can also be used for this purpose. In a scientific study at Fraunhofer IPA, we were able to prove that the AI approach works better in the field of maintenance than previously used heuristics and mathematical optimization approaches. This means that more was produced because there were fewer unplanned shutdowns. And production costs were lower because there were no so-called fatal failures, only planned ones.

In essence, AI should be viewed as a tool. And as with any other tool, you have to decide whether and when it makes sense to use it or not. Machine learning is suitable when the cause-effect relationships are not known or cannot be described, but sufficient data are available instead. So, for example, if a mathematical model is available, as is the case with many control problems, then AI is usually unnecessary or merely an addition to the existing process.

And another aspect in the context of making sense of machine learning in productions is, of course, that machine learning relies on data. And this data is unfortunately not available everywhere. For example, this can be the case with the quality inspection with cameras in production just mentioned. It would be helpful if sample data of defects were available in order to be able to reliably detect exactly these. But in a good production, there should actually be few defects. Therefore, in order to train an algorithm that can detect such defects, however, we are working on artificially generating the data. Or an algorithm is chosen that does not detect a defect, but is good at judging whether the machine is still in a normal state. This is because there is an abundance of data from the normal state in a well-run production.

What are the disadvantages and risks? One caveat might be, “The system eventually takes over all operations, leaving the human on the outside – control is gone!” Are these objections justified?

Of course, we are aware of these reservations, and I also think it is very important to take them seriously and to ‘take along’ the users of an AI application. Because in the short to medium term, it will definitely be the case that AI-based technologies will support humans, perhaps performing a specific subtask alone and autonomously, but humans will still have a central function in the production environment.

To this day, after all, in the field of AI, Steven Pinker’s famous quote holds true: “The hard problems are easy and the easy problems are hard.” This means that problems that are easy for humans, such as creativity, manipulation, or perception, are very hard for AI. Other problems, such as lifting heavy objects or calculating with large numbers, are difficult for humans but easy for artificial systems. So there are many good reasons why humans and AI systems can and should work hand in hand. AI can take on tasks that are very monotonous or too computationally intensive for humans, for example, allowing human workers to focus on higher-value tasks that benefit from human strengths. To achieve this, a human-centered approach must be taken in the development of AI systems, i.e., AI systems should be based on people’s needs, values, and well-being in order to gain trust and acceptance and also to always allow people to be in control. In this way, an AI system becomes operable for everyone: it perceives, understands, mimics, and actively supports humans.

What benefits can a manufacturing company derive from the use of AI?

Of course, it’s not that easy to give a blanket answer, because it depends on the prerequisites and goals of the individual company in order to be able to assess exactly which advantages the use of AI offers. In principle, AI, or more precisely the use of machine learning, enables a higher degree of autonomy (in the sense of “automation of automation”) and often better accuracy or problem-solving skills in the execution of a specific task. In concrete terms, this can mean that a company saves money when it carries out maintenance planning based on AI because, as mentioned above, there are fewer downtimes and failures. If AI is used to optimize production planning and control, knowledge that was previously tied to individuals can now flow into the AI system, making the knowledge more widely and quickly usable.

AI can therefore help to optimize processes and make them more efficient. If you think about robotics, AI reduces programming efforts because each individual process step no longer has to be programmed manually; instead, the robot system can adjust itself to deviations in the process or new workpieces and adapt its parameters accordingly. This is particularly crucial for increasingly personalized production, where the programming effort required to date could quickly make robot use uneconomical. Last but not least, AI can simplify challenging tasks such as reaching into a box for robots, for example, by enabling powerful image recognition to perceive reflective or mirroring objects well, or even by enabling the robot system to recognize whether components are snagged and how this can be resolved.

How can SMEs get started using AI in a practical way?

We have already carried out a triple-digit number of AI projects with SMEs. From these extensive experiences we know that the interest is mostly present in principle and sometimes also great. But often there is alternately a lack of time and/or money and especially a lack of expertise. Last but not least, there is often a simple lack of data or its sensible processing in order to implement applications with machine learning at all, because at least this AI subarea is based on more or less large amounts of data, which should be available or must be generated in real or in simulations.

In my experience, there are four points worth considering to make AI solutions pay off quickly in enterprises:

- Start small, think big: Look for “low-hanging fruits” first. This yields quick results, initial findings and thus argumentation aids within the company. With this experience, you can tackle bigger challenges.

- Start early: Identify meaningful uses for AI early on. Use short development cycles to move forward quickly and be able to counteract difficulties in an agile manner. That’s how you get prototypes quickly.

- Pay attention to the benefit: Ultimately, an AI project stands and falls with its added value. Let the business department drive the issue and not necessarily the IT department.

- Take everyone with you: Don’t forget the employees. If you can convince them of the benefits of an AI project, this will prevent unnecessary blockades.

Especially if there are teething problems or lack of clarity about the advantages and benefits of AI for a company, I recommend seeking expert advice. For example, the AI Progress Center of the Fraunhofer Institutes IPA and IAO offers various funding formats. These address beginner questions, provide brief feasibility studies, or allow for the construction of a demonstrator.

How do you or your institute demonstrate the use of AI in industrial production processes at trade shows, such as the next Motek in Stuttgart in October 2022?

At our institute, we have a number of demonstrators and exhibits that we will certainly present this year at trade shows, but also at in-house events. Let’s hope that towards summer more presence will be possible again…

With the exhibit “AI Picking” we show how machine learning and simulations significantly improve the application in terms of autonomy and performance. The scientists demonstrate this using the example of a robot that grabs objects from an undefined position from a box. For this purpose, an AI-based object pose estimation provides robust and accurate object poses in a few milliseconds. New objects can be taught in quickly and easily on the basis of a CAD model. The software can also detect and solve the entanglements already mentioned above and also robustly handle packaging material. The robot had already been extensively trained in the simulation, and we then transferred this knowledge to the real application. The software also generates and evaluates gripping poses based on this knowledge.

One software for assembly automation is NeuroCAD. It uses machine learning methods to analyze component properties and use them to determine the extent to which a component is suitable for assembly automation. Users can upload their STEP files free of charge on a website and find out within seconds how easy or difficult it is to separate a component. The tool also evaluates the gripping surfaces and the alignability of the component. In addition, the neural network states a probability that it is correct with its result.

From my research group comes another demonstrator that addresses many industries and applications. With it, we demonstrate how AI processes that have so far operated in a non-transparent manner can become comprehensible and explainable. As I mentioned above, transparency or the so-called “white box character” of AI applications is becoming increasingly important – both because of legal requirements and to build trust on the part of users. And because this topic is becoming increasingly relevant, we have the right offering here for all user needs: from the identification of use cases to the creation of explainable AI models and their use in customer applications to the generation of explanations for already trained AI models and procedures for creating transparency.

Vita – Univ.-Prof. Dr.-Ing. habil. Marco Huber: After studying computer science and successfully completing his doctorate at the University of Karlsruhe (TH), Prof. Huber headed the research group “Variable Image Acquisition and Processing” at Fraunhofer IOSB in Karlsruhe from 2009 to 2011. Subsequently, he worked as a senior researcher at AGT International in Darmstadt until 2015. From April 2015 and until September 2018, Prof. Huber was responsible for product development and data science services of the Katana division at USU Software AG in Karlsruhe. At the same time, he taught as a private lecturer in computer science at the Karlsruhe Institute of Technology (KIT) after successfully completing his habilitation. Since October 2018, he has held the professorship for cognitive production systems at the University of Stuttgart. At the same time, he heads the Image and Signal Processing and Cyber Cognitive Intelligence (CCI) departments at the Fraunhofer Institute for Manufacturing Engineering and Automation IPA in Stuttgart. His research focuses on machine learning, explainable artificial intelligence (xAI), sensor data analysis, image processing and robotics in the production engineering environment.