Current topics for the Bondexpo trade fair

8. January 2025

Motek/Bondexpo 2025: Three Trade Fair Days for Greater Efficiency

The 43rd Motek international trade fair for automation in production and assembly will be held together with the 18th Bondexpo international trade…

14. October 2024

Practical Solutions for Automation in Production: Motek/Bondexpo 2024 was a Great Success

The 42nd Motek international trade fair for automation in production and assembly, together with the 17th Bondexpo international trade fair for…

11. October 2024

Motek/Bondexpo 2024 – Trade fair films ‘Statements & Scenes’

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing…

8. October 2024

Motek/Bondexpo 2024 has started: 409 exhibitors from 19 countries showcase innovations in the field of production automation

The traditional Motek/Bondexpo trade fair duo has started: 409 exhibitors from the production automation sector will meet in Stuttgart from 8 to 11…

16. September 2024

Motek/Bondexpo 2024 is Ready for Take-Off

The Motek/Bondexpo technology and business platform is ready to go. Suppliers and users of production automation systems will meet in Stuttgart for…

22. August 2024

No fear of AI at Motek/Bondexpo 2024

Companies in the manufacturing industry are facing major challenges – efficiency, cost-effectiveness, conservation of resources and a shortage…

9. August 2024

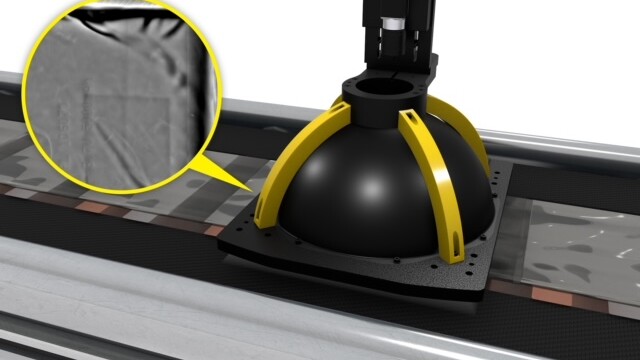

Motek/Bondexpo 2024: Object recognition with trevista Line Scan

Trevista-dome-pouch-cell-inspection-with-inset. Image: AIT Goehner At Motek 2024, AIT Goehner will be presenting trevista Line Scan, the perfect…

22. July 2024

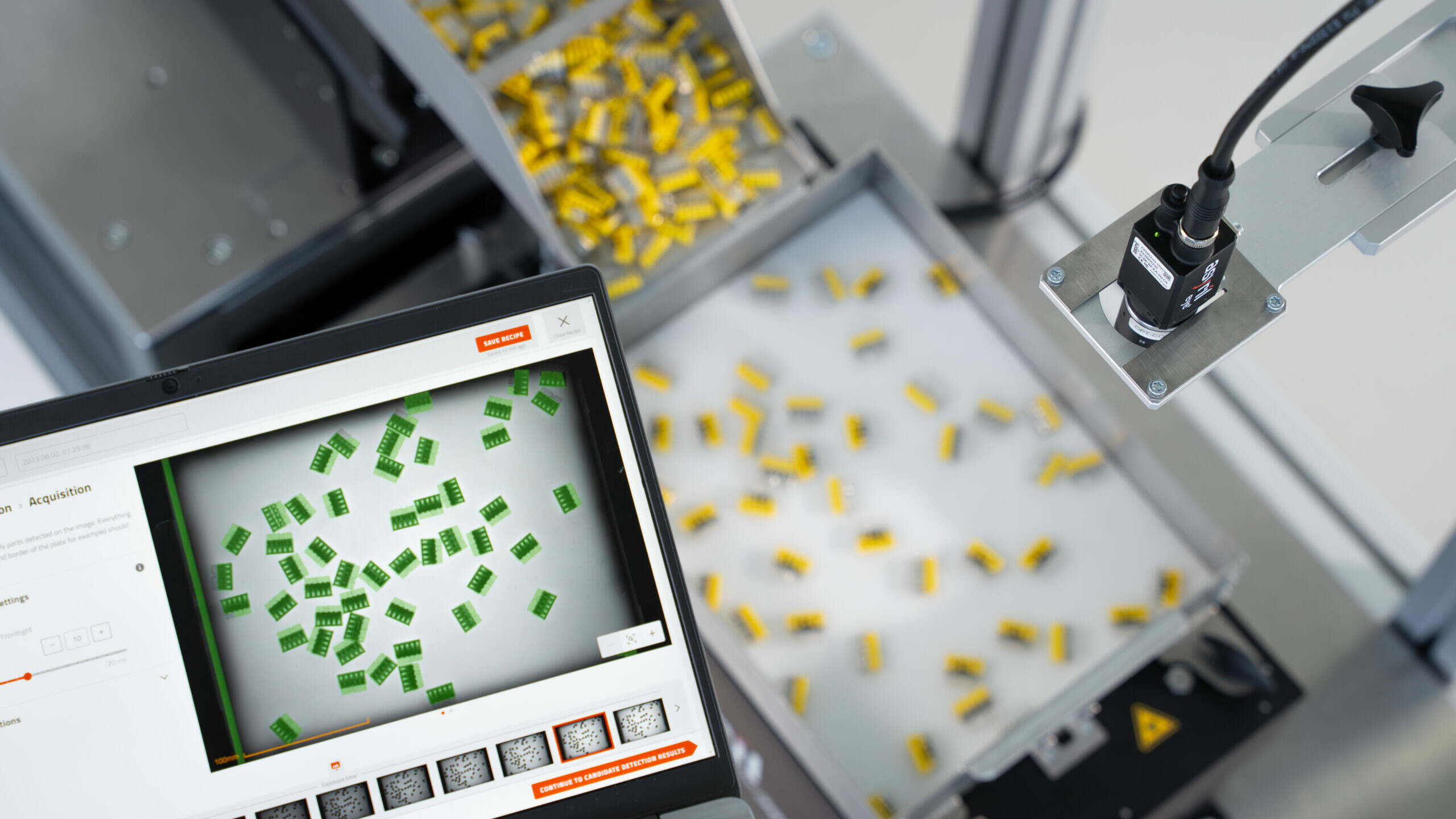

Automatic Parts Detection: Solving Complex Handling Tasks with AI

Object detection makes it possible to automate difficult production steps. Photo: Cambrian Robotics Cambrian Robotics will showcase its 3D vision…

8. July 2024

Disentangling & Feed – and Now Screwing Too

MAFU Automation is a member of the MAFU Group of companies. (photo: MAFU) MAFU with headquarters in Rosenfeld, Germany, is specialised in…

18. June 2024

Cutting-Edge Technologies for the Challenges of Automation at Motek/Bondexpo 2024

Production automators will have to work even more economically and efficiently in the future. The 42nd Motek international trade fair for automation…

18. June 2024

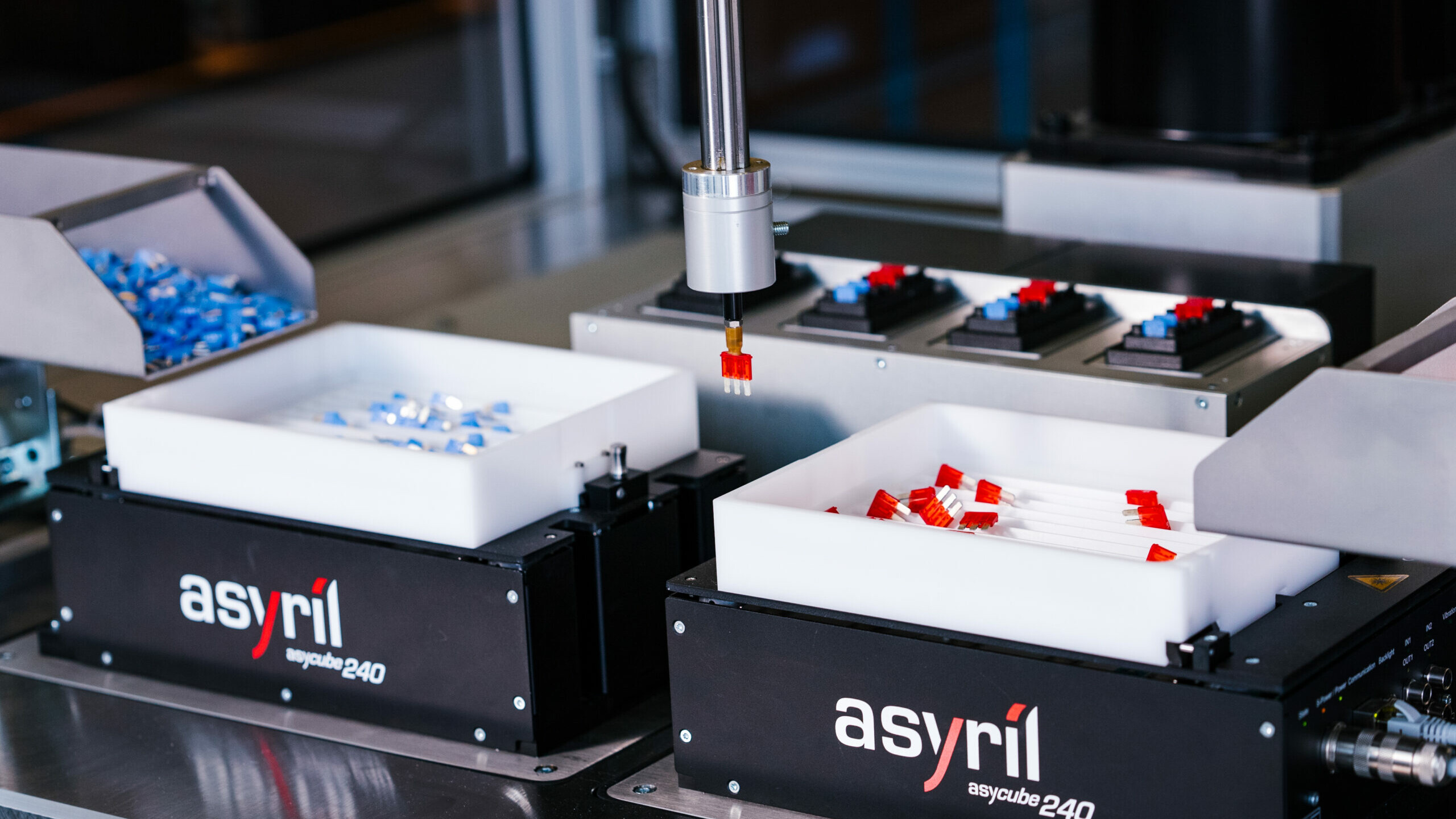

Feed Technology: Cutting-Edge Engineering for Meeting the Challenges of Automation

Participation at Motek is very important for Asyril because we establish direct contact with potential customers and partners at the event, and…

3. June 2024

Feed Technology – Fully Digitalised

“Digital Feeder” Simulation Programme. Photo: RNA Feed systems are indispensable for automation in assembly and production. A diverse range of…